Although it is a rare occurrence, data centres do occasionally experience a break in the action.

This usually happens during holidays and periods of high user demand. At these times, nobody wants to rock the boat by implementing major projects that could jeopardize availability or uptime.

Many data centre managers that we talk to use slowdowns as an opportunity to take care of all those tasks they have been putting off in favour of more urgent work throughout the year.

Implementing these fixes requires relatively little effort or investment, but it can deliver a big pay-off.

Just as importantly, the fixes can all be done with very little risk of downtime.

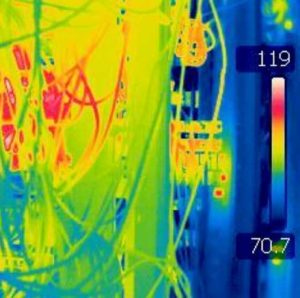

Heat build-up around unmanaged cabling at the back of a rack.

If you have added or swapped out equipment during the past year, you may not have had time to tidy up the cabling within the rack. When left unmanaged, network and power cabling can create significant airflow blockages that drive up temperatures within the rack. The adjacent thermal image clearly shows the heat build-up (in red) around unruly cables in the back of a rack.

There are several easy ways to tidy up your cables and improve airflow within the rack. These include:

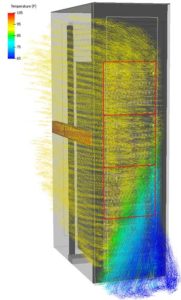

For years now, ASHRAE have recommended the use of blanking panels to close empty u-spaces within the rack. This avoids the recirculation of hot air back through the rack where it can re-enter equipment inlets (see image). Major server OEMs like HP and IBM clearly state in their product manuals that blanking panels should be used to ensure the optimal operation of the equipment.

Hot air exhaust air making its way to equipment inlets via open u-spaces.

The great news is that blanking panels are one of the easiest and most affordable ways to improve airflow and save on operating costs. A recent case study by Upsite showed that one high-density facility was able to save over one hundred thousand dollars in annual energy costs by installing blanking panels.

If you make just one fix during your next slowdown, this is the one to make!

Another common and easily fixable issue that we see in data centres is the failure to adequately seal openings in the raised floor.

Proper sealing of floor openings can be done in variety of ways. The most common is to install raised-floor grommets that use brushes or other sealing materials to block airflow around cables. For openings that will not require additional cable feeds in the future, foam sealant provides a highly effective permanent solution.

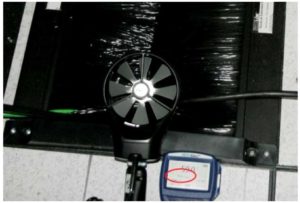

Even if you have already installed one of these solutions, it is important to check them on a regular basis. We have seen many cases of improperly installed solutions or ones that would benefit from an upgrade. The adjacent image shows an example where our testing tools revealed a high volume of air flowing through an improperly applied grommet.

Cool air escaping through brush strips in floor openings

No data centre is ever fully finished or completely optimized. As your facility grows and changes you’ll want to come back to this list often. Every slowdown gives you a great opportunity to take care of these important but often neglected best practices.